How it works

Algae Control

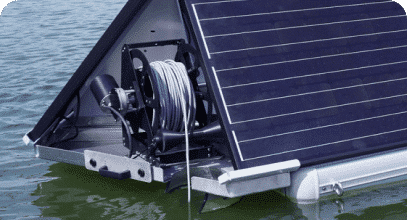

Industrial Wet emits specific ultrasonic frequencies to control algae in smaller water surfaces.

• Ultrasound is transmitted throughout the water body

• For smaller reservoirs, clarifiers

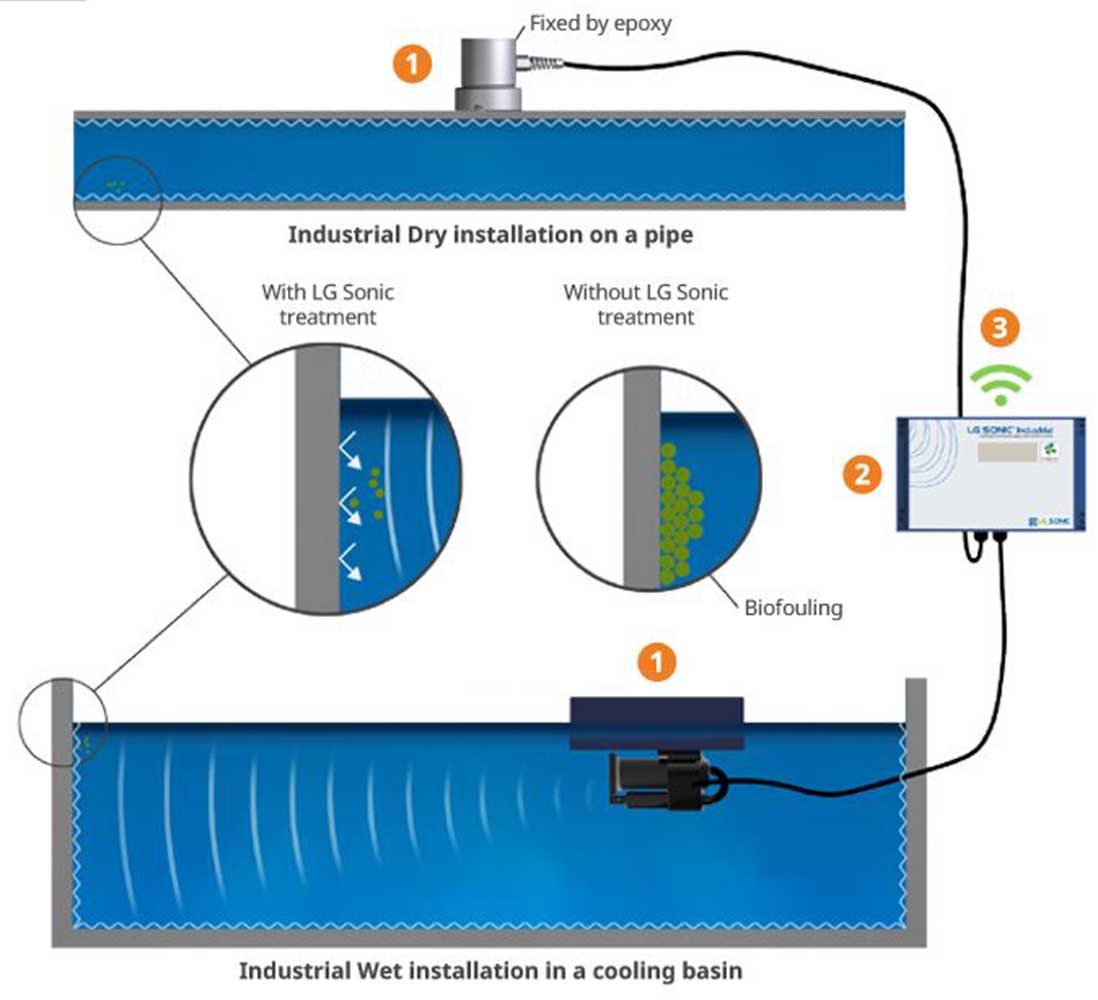

Biofouling Prevention

Industrial Dry uses ultrasound to prevent biofouling and chemical usage in cooling towers, heat exchangers, and pipes.

• Ultrasound is transmitted through the dry side of a surface

• Prevent the growth of biofouling

Biofouling issues

Biofouling in closed-loop systems can result in serious negative side effects such as increased chemical consumption, corrosion, increased power requirements of the system, and health and safety implications due to the growth of Legionella or other potentially harmful organisms.

Advantages of our technology

- Prevent the growth of biofouling

- Reduce chemical expenses

- Prevent clogging of filters and pumps

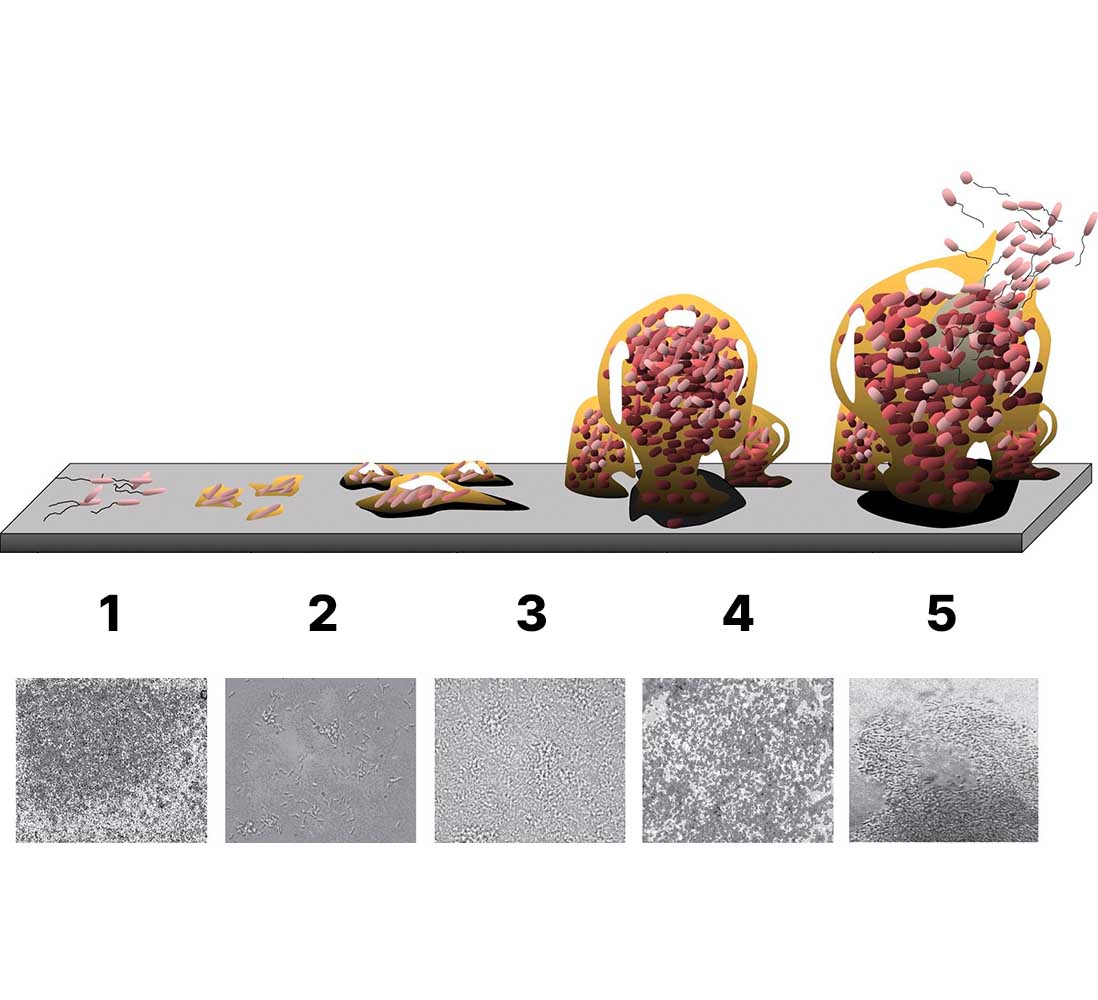

How ultrasound prevents biofouling growth

Specific ultrasonic frequencies, waveforms and amplitudes can be utilized to prevent the formation of biofouling. Biofilm formation starts by bacteria attaching to a surface. The ultrasonic sound waves of LG Sonic create resonance around the solid surfaces within the water, thereby preventing bacteria to adhere to a surface.

- Prevent bacteria from settling on a surface in the primary stages of biofilm formation

- Alter the structure of an existing biofilm, eventually breaking it down

- Control potential algae attaching to a biofilm

No use of cavitation

Some ultrasonic biofouling control solutions use cavitation to prevent biofouling, which is a phenomenon where high-power ultrasound causes intense heat pressure and the formation of hydrogen radicals.

These radicals may kill bacteria and other organisms but also cause oxidation reactions and may degrade anticorrosion layers.

- Not harmful for marine life

- Longer product lifetime

- Longer treatment range

Installation and maintenance

Both the Industrial Wet and Industrial Dry systems are easy to install and require minimal manpower.

The rugged design allows for minimal maintenance and few check-ups.

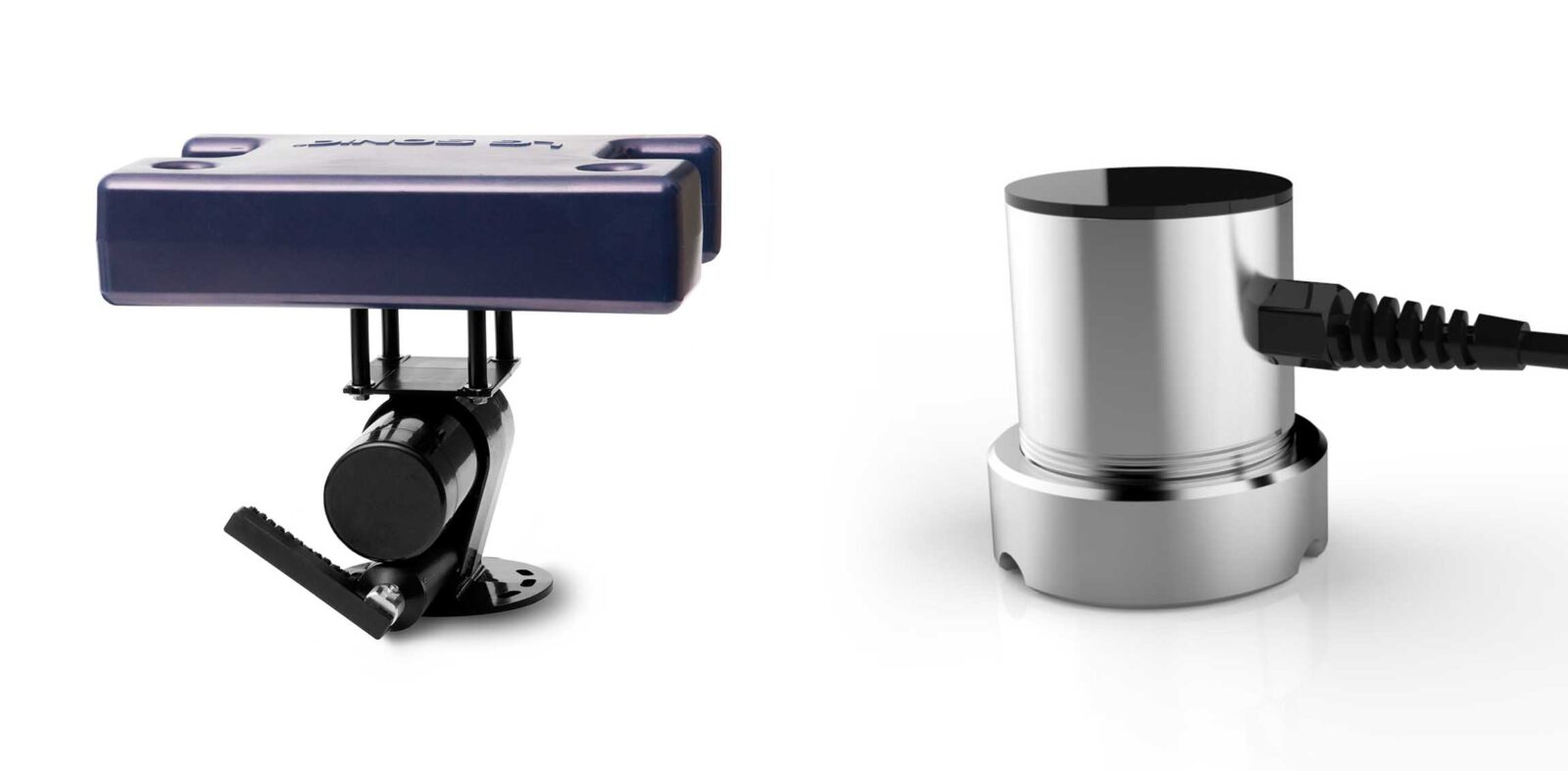

Industrial Dry

Industrial Wet

Industrial Wet

- Installed: submerged

- Integrated Aquawiper

- 200m treatment range

- Chameleon Technology

Industrial Dry

- Installed: pipe/dry surfaces

- 10m/30ft treatment range

- No use of cavitation

- Chameleon Technology

Control box

- Weatherproof

- LCD display

- 12 ultrasonic programs

- GSM/GPRS control