Real-time Heavy Metals Monitoring

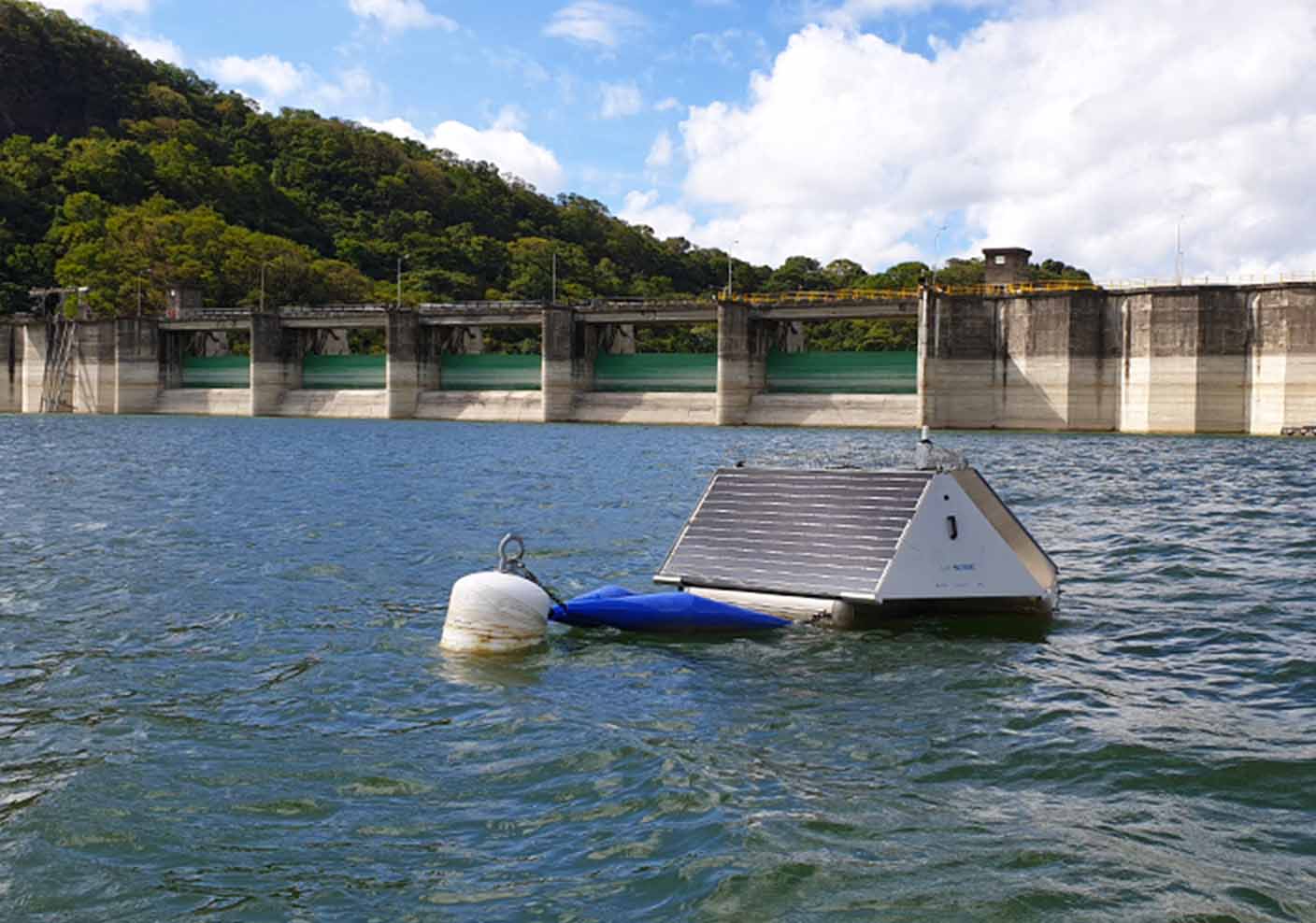

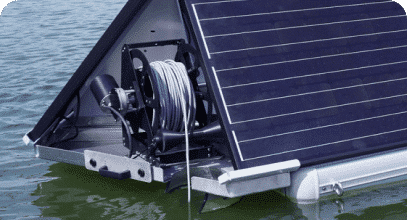

Autonomous proactive monitoring

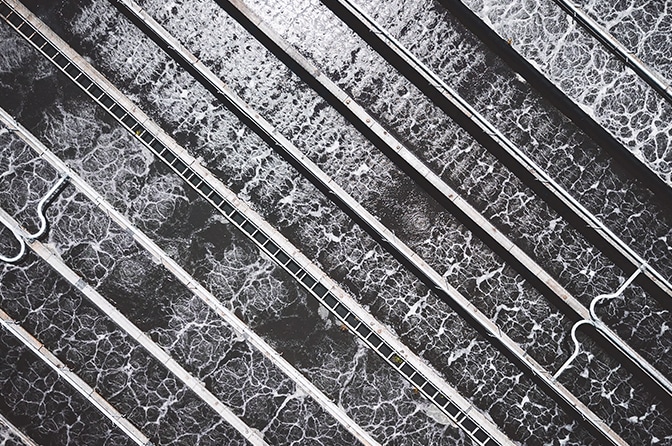

The LG Sonic Trace and Heavy Metals Monitoring system offers fully autonomous, modular monitoring for various water sources, including process streams, effluent discharges, rivers, and drinking water. It efficiently tracks up to 23 metals with high-frequency analysis and features programmable alarms for detecting anomalies or system faults that might only detected at final discharge. With its real-time alert system, operators can swiftly respond to unexpected metal level increases in processes or waste, enabling prompt preventative actions and process adjustments for optimal efficiency.

Environmental regulations compliance

In response to stricter heavy metal effluent regulations, industries increasingly require precise monitoring to avoid penalties and maintain compliance. The LG Sonic Trace and Heavy Metals Monitoring systems offer a reliable solution, ensuring accurate reporting and data transparency. These systems meet the growing regulatory demands, aiding industries in sustaining market access and consumer trust. They are essential for companies aiming to fulfill environmental regulations and achieve their sustainability goals, aligning with responsible and eco-conscious business practices.

Reduce operational costs

Chemicals are often used to remove metals from various water sources. As operators may have limited knowledge of the actual metal concentrations present, these chemicals are often added in excess to ensure regulatory compliance. By leveraging our LG Sonic Trace and Heavy Metals Monitoring system, operators can measure metal levels accurately, optimizing chemical use and significantly cutting chemicals, labor, and pre-treatment costs. Compatible with most plant control systems, it automates wastewater and effluent treatment, enhancing water quality management.

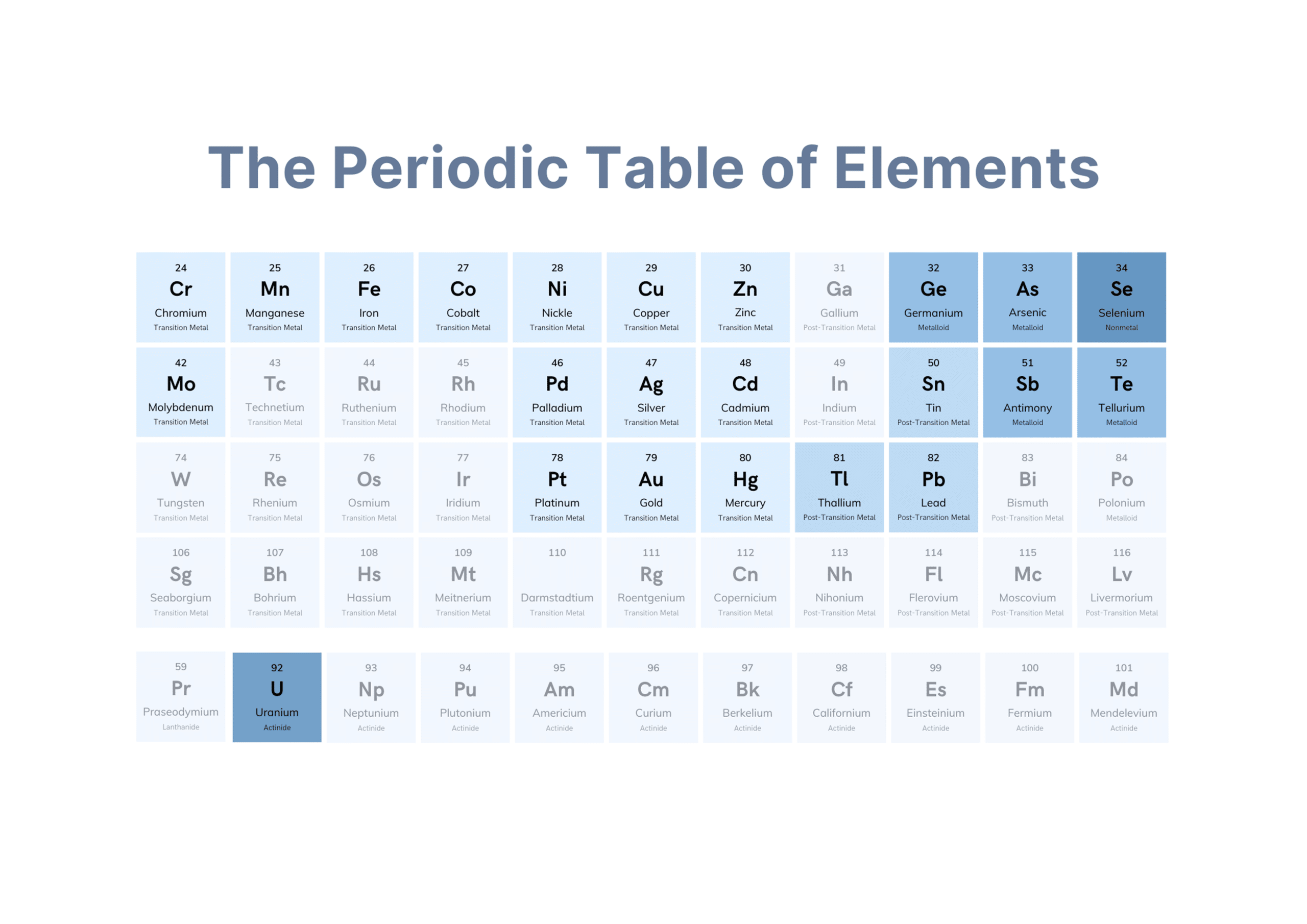

Up to 23 monitored metals

Our advanced monitoring system comprehensively tracks and manages a wide range of critical metals. This includes essential metals like Silver (Ag), both Arsenic (As(III)) and total Arsenic (As(total)), Gold (Au), as well as contaminants such as Cadmium (Cd), Cobalt (Co), Chromium (Cr(VI)) and total Chromium (Cr(total)), and Copper (Cu). Additionally, it enables precise monitoring of Iron (Fe), Mercury (Hg), Manganese (Mn), Molybdenum (Mo), Nickel (Ni), Lead (Pb), Palladium (Pd), Antimony (Sb(III)), Selenium (Se(IV)), Tin (Sn), Tellurium (Te), Thallium (Tl), Uranium (U), and Zinc (Zn), providing a comprehensive solution for diverse industrial and environmental applications.

High precision and sensitivity

Our system utilizes internationally recognized voltammetry (ASV and CSV) technology, which provides quick and accurate determination of metals at the micrograms per liter (ppb) level, directly comparable with laboratory methods such as Atomic Absorption Spectroscopy (AAS) and Inductively Coupled Plasma (ICP) analysis. It has high levels of accuracy and repeatability with very low detection levels (0.5µg/L to 10µg/L). LG Sonic provides a range of standards, electrolytes, and other reagents used in the routine operation of the system. The use of these high-purity reagents ensures the longevity of the electrodes and the reliability of the analyses.

Applicable in various industries

The LG Sonic Trace and Heavy Metals Monitoring system is crucial for river water monitoring, drinking water protection, and municipal incineration wastewater management. It’s pivotal in mining operations, power plant scrubber water, and effluent management in automobile and aerospace manufacturing. Additionally, the system is employed in metal smelting, battery production, land/water remediation, semiconductor effluent management, agricultural water protection, and desalination, showcasing its wide-ranging importance for environmental compliance across various industries.

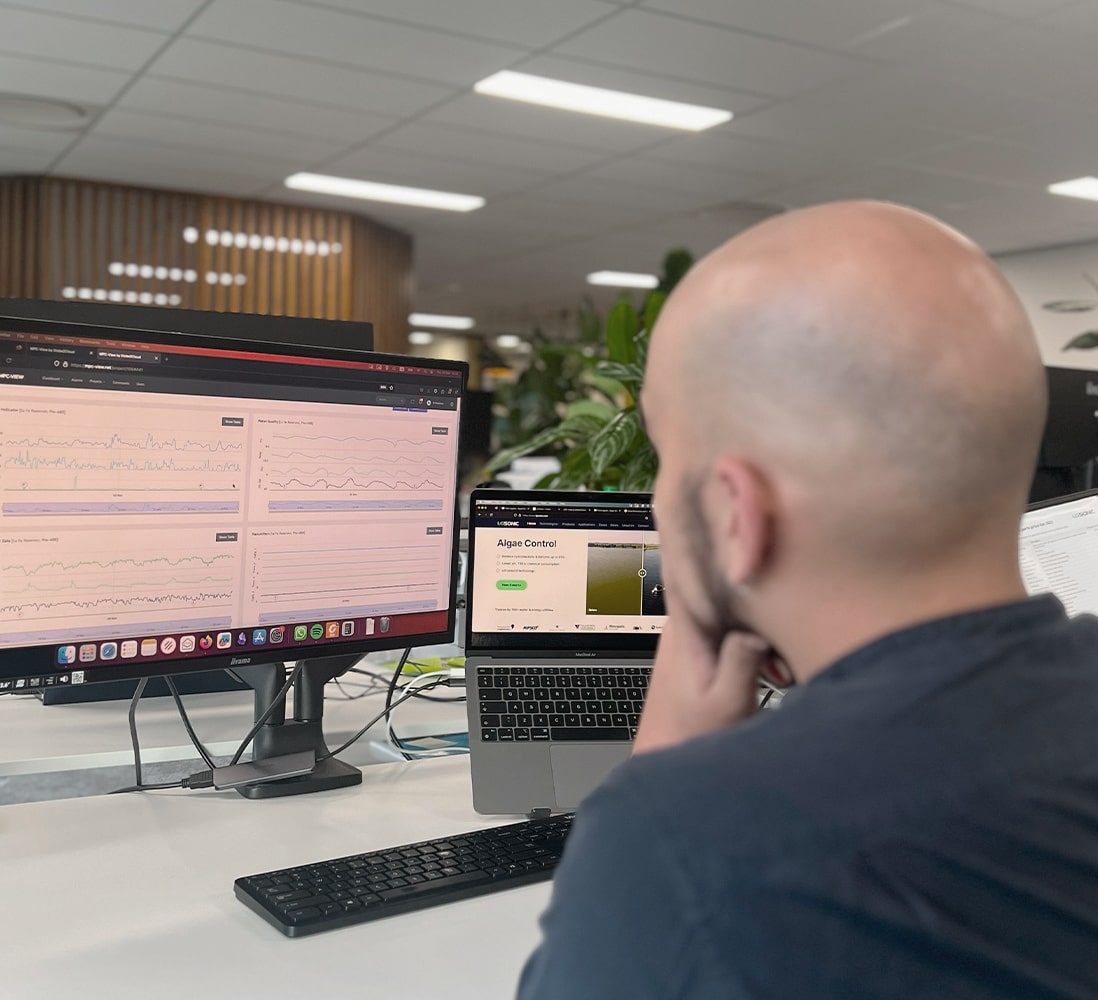

Remote access and integrated data

With the capability of our system to gather data in real-time, we offer a suite of secure communication options, including wireless connectivity. This allows for the analytical results to be accessed and visualized in real-time via a dedicated online software platform. The integrated data communication feature of the system ensures an effortless link to the process control room, facilitating its integration into automated plant control systems. This real-time data integration is pivotal for optimizing plant performance and ensuring that decision-making is informed by the most current data insights.

Request For Information

LG Sonic Trace and Heavy Metals Monitoring